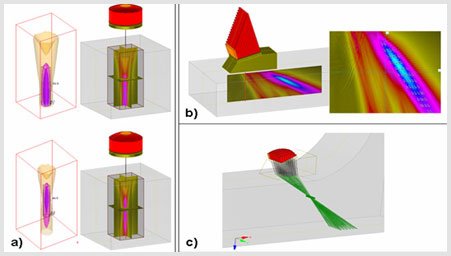

Our Ultrasonic simulations capabilities allow optimizing the design of a testing procedure by accounting for most of the influent parameters: the probe, the geometry, the material and the flaws to be detected. By combining and varying all these parameters, it is possible to select the most efficient method regarding the test to be carried out, or even evaluate the performance of a given existing procedure. Simulation is a major tool for cost reductions. The possibility to make some parametric variation on any setting parameter allows anticipating the test for instance during the conception stage of a component, or minimizing the number of mock ups to be manufactured to demonstrate the performance of a given testing procedure. R&D effort includes hardware and software development. Among our team of partners engineers, we have experts in acoustics, vision, transducers, mechanical design, software and electronics. This allows streamlined application development to meet your needs. Some of the work include:

- Vision and Ultrasonic Feasibility studies

- Software and new algorithm development

- Beam propagation and its interaction with flaws or specimens

- Validation of inspection processes

- Design and selection of probes

- Assessing deterioration factors such as probe orientation and geometry change

- Qualification of the process: defect angles, surface conditions, curvature, material composition

- Study of parameter effects for POD curves simulation